Optimization of the anticoincidence system for the detection of radioactive xenon by gamma spectrometry system

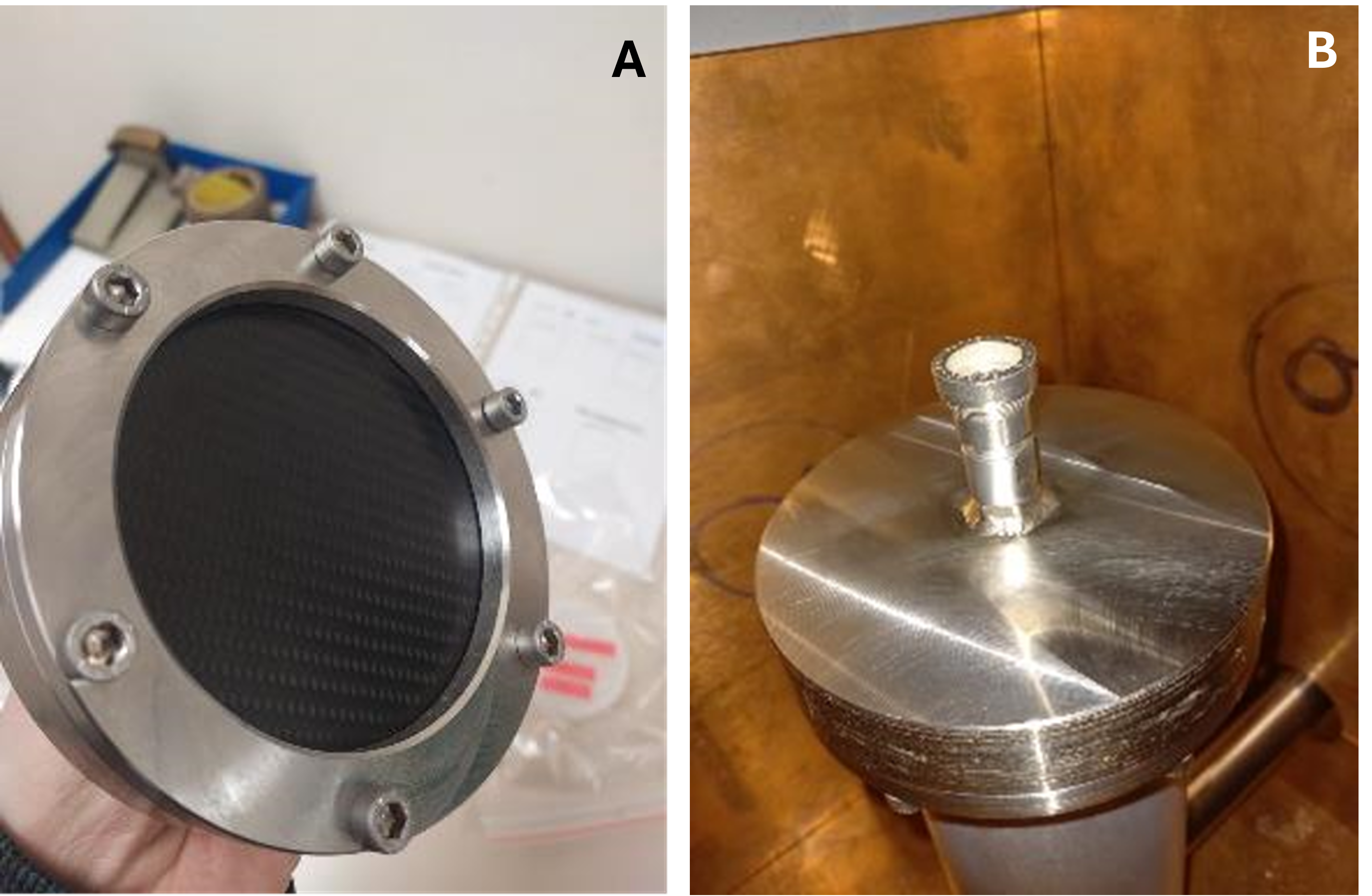

The design of a new xenon measurement cell was optimized for the best fitting on the germanium end cap detector, also the height of the cell was reduced in order to have a more favorable surface/volume ratio and in this way exposing a higher volume of gas to the detector window.

The starting cell design has been provided by the Seibersdorf Labor GmbH. Such cell is made of electrolytic copper. The chosen material for the cell structure was austenitic stainless steel AISI 304 for its durability and robustness.

The use of electrolytic copper is still preferable for its extremely high purity, but it has the downside of being very ductile and the cell could potentially be deformed with the laboratory common use. Furthermore, due to the scarce availability of electrolytic copper on the market and its very high cost the AISI 304 steel was the best compromise.

The new cell was checked by gamma spectrometry to verify the absence of potential radioactive contamination (e.g. cobalt-60 impurities or other possible impurities that can be present in the alloy from the industrial processing). The new carbon fiber window was reduced in thickness to 0.5 mm against the 0.6 mm of the Seibersdorf Lab cell. To ensure the sealing, a silicone paste was added to the steel-carbon contact point. Vacuum and pressure tests were carried out to verify the airtight. Diameter of the window is 90 mm, the same as our detector head. The internal thickness of the cell is 12 mm with a volume of 76 ml. The cell has been also equipped with a Swagelok gas valve for sample injection.

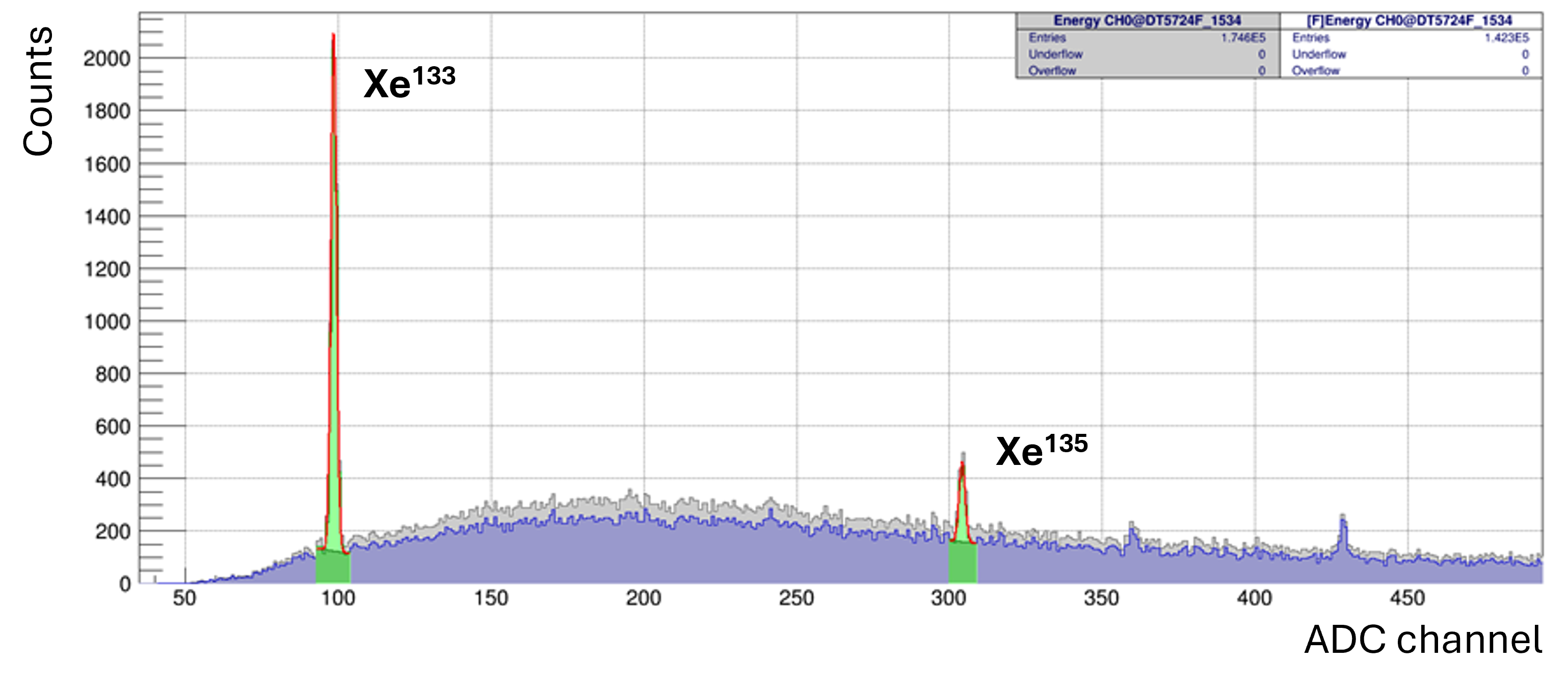

In order to verify the improvement on xenon detection of the new cell design, respect the old Aluminium cell previously used at the ENEA lab, dedicated background measurements have been performed for the two cells. The two cells are washed several times with helium gas and then measured for background evaluation.

The new stainless-steel cell shows better performance with less background counts for 214Pb and 214Bi, coming from the decay chain of radon, compared the old Aluminium cell. In addition, the very short-lived Xe-135 was identified successfully with the new setup where the anticoincidence system is coupled with the stainless-steel cell. That was possible due the whole analysis process has been sufficiently fast: a second analysis run on the following day was not able to identify the Xe-135 due to its very short half-life of only 9 hours.

Chiara Telloli

ENEA

chiara.telloli@enea.it

Antonietta Rizzo

ENEA

antonietta.rizzo@enea.it