We successfully finished the SafeG project

The global objective of the SafeG project was to further develop the GFR technology and strengthen its safety. The project supported the development of nuclear low-CO2 electricity and industrial process heat generation technology through the following main objectives:

- To strengthen safety of the GFR demonstrator ALLEGRO

- To review the GFR reference options in materials and technologies

- To adapt GFR safety to changing needs in electricity production worldwide

- To bring in students and young professionals, boosting interest in GFR research

- To deepen the collaboration with international non-EU research teams

Aim of the SafeG Final Workshop was to present how these goals were achieved and by what specific project activities, findings and deliverables. The audience was informed about advancements of the SafeG to the areas mentioned above, about produced reports, lessons learnt for further steps in development and research, as well as about current trends and possibilities in area of GFR development, materials, technologies and safety.

An invitation for the SafeG Final Workshop was extended to several target group, especially to:

- Students and young researchers in nuclear field with aim to attract them to topic of GFR

- Nuclear research community with aim of increasing interest of GFR and related topics

- Members of linked initiatives and networks with goal to promote concrete project results and findings – V4G4, Generation IV International Forum, ESNII.

The event was attended by 43 participants in person and 10 remotely connected.

The event gave an opportunity to gain general knowledge of current status of research and development related to GFR. Audience got know information on improvements of GFR refractory core and fuel design, GFR materials and advanced manufacturing process outcomes in the development of safety of the GFR or needs for material standardization specific for GFRs. The speakers presented details on S-Allegro experiments, ALLEGRO core CFD and nitrogen injection simulations. The event also presented successful education and training activities and events.

During the project implementation we made a significant step towards improvements in various fields of ALLEGRO demonstrator design. According to the essential outcomes of the project, the workshop was divided among four most significant fields we have been working during the project period – GFR core and Fuel Design, GFR material R&D, Safety-related R&D and Education and Training.

GFR Core and Fuel Design

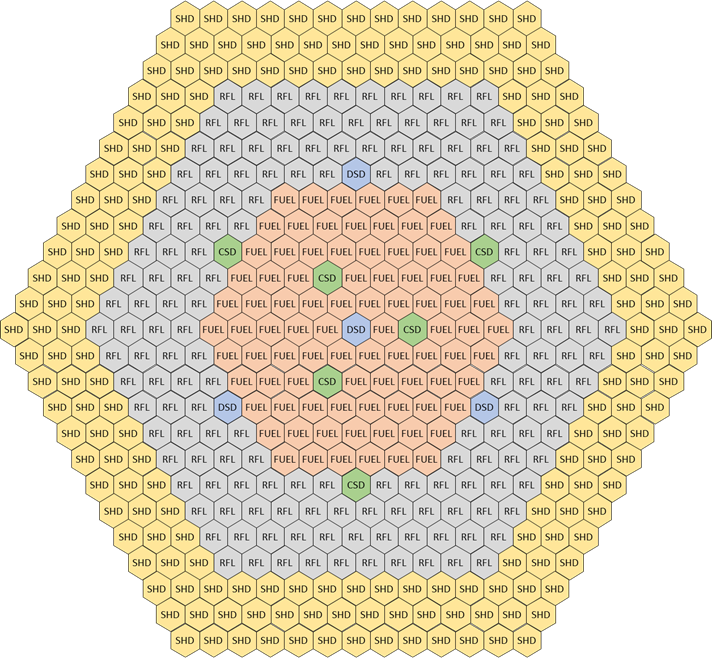

- Refractory core optimization– methodology of control and shutdown system, optimization processes and results,

- Reflector optimization - requirements of reflector materials, excess reactivity and peaking factors at BOC, assembly-wise power distribution, neutron spectrum of fuel assemblies, pin-wise power distribution,

- Shielding optimization - examination of potential shielding materials, examination of coolant channel arrangements

GFR material R&D

- Material research - details on selected materials for HTGR systems, innovative cladding materials development & testing, ODS material development and compatibility of materials with media in GFR conditions

- Advanced manufacturing process - overview of advanced manufacturing processes development of safety critical GFR components for ALLEGRO, implementation of materials with better performance and processes with enhanced capabilities, characterisation studies to qualify and/or quantify process suitability for design and construction of GFRs and additive manufacturing (AM) for critical parts fabrication

- Needs for material standardization specific for GFRs - standardization and codes in the nuclear industry, especially in relation to GFR, how were meet within the project, how to add new materials and processes into the code, ensuring validity of the data in the codes and topic of uncertainty and limitations of usage of the codified data

Safety-related R&D

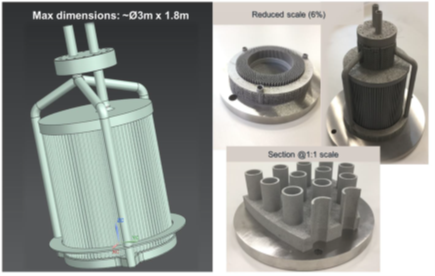

- S-Allegro experiments - detailed background, its layout with emphasis on loop design parameters, heating power and ability to simulate LOCA/LOFA and heavy gas injection

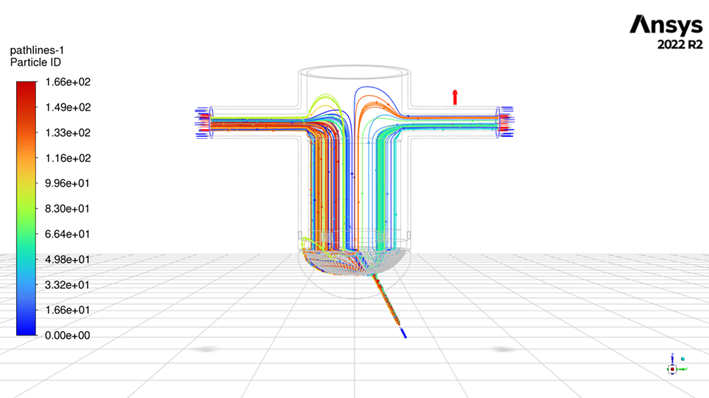

- ALLEGRO core CFD simulations - details of ALLEGRO Core CFD Simulations with focus on models of individual sub-assemblies, a model preparation strategy – CFD Simulation of Core Cooling LOFAs

- Nitrogen injection simulations – related to selection of initiating event, phenomena identification and selection of relevant inputs, TH simulations and design change proposal and comparison with reference solution

- Assessment of technology readiness level of GFR and R&D needs - various aspects of TRL on a level of benefits and limitations, assessment method, TRL of GFR and remaining challenges and R&D needs

Education and Training

- Education and On-job Training Activities of the SafeG - realization of the SafeG GFR summer school organized in summer 2022 in Pilsen, SafeG Workshop on advance modelling techniques organized in summer 2023 in Cambridge, as well as thermal-hydraulics benchmark focused on PhD. students and young professionals, successful result in area of exchange students between universities involved in the SafeG and diploma theses connected to the project.

- Results of the SafeG benchmarking activities - results of the thermal hydraulic benchmark on S-Allegro ITF and CFD benchmark on PIROUETTE facility, TH model development and validation, steady state TH calculations, on-transient TH calculations, flow Straightener CFD analyses and Rod Bundle CFD analyses

Slavomír BEBJAK

VUJE

slavomir.bebjak@vuje.sk