News from ETSON and its members*

In 2023, four teams participated in the final phase. A Science slam was organized At BEL V in Brussels by the "Junior Staff Program" on October 11th.

Jožef Stefan Institute, as one of the TSO organizations in Slovenia, is currently involved in support of the Slovenian Nuclear Safety Administration activities during the unplanned Krško Nuclear Power plant outage.

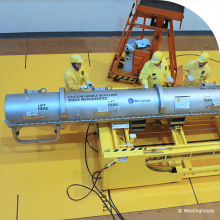

This autumn marked a significant event in the field of nuclear energy, not only for Ukraine but also globally. Ukraine was the first country to load Westinghouse nuclear fuel into a VVER-440 reactor at one of its NPPs. Until now, Ukrainian reactors of this type used only russian fuel. Thus, Ukraine has become the first nation to achieve independence from russia in the supply of fresh nuclear fuel for operating VVER-1000 and VVER-440 Soviet-era reactors.

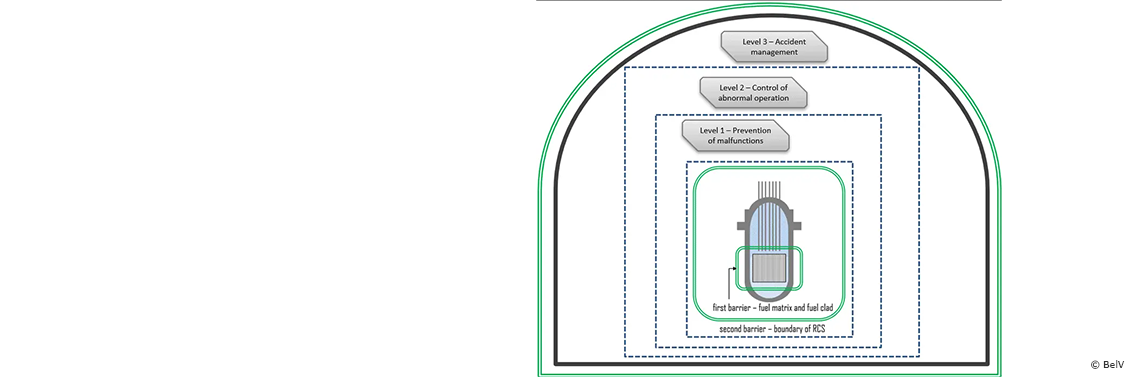

Since the early 2000s, there has been a significant increase in the number of innovative reactor designs worldwide. These designs are based on unique solutions and approaches not yet seen in operating nuclear power plants nor previously used in the nuclear energy sector.

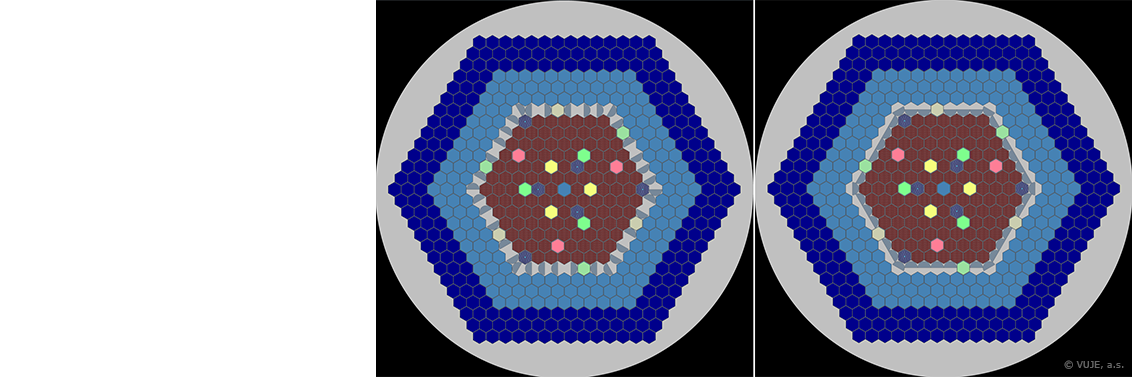

VUJE implemented several changes to the thermohydraulic model, delivered code for severe accident and two new 3rd party systems.

The aim of the ongoing project is to make the FSS more representative and in line with the real control room.

Sacca di Goro, in the Adriatic Sea (north of Italy), is one of the areas affected by widespread radioisotope contamination after the Chernobyl accident. A campaign was recently conducted in its lagoon to verify the current status of some radionuclides such as 137Cs, 40K, 238U, 232Th and 226Ra in sediments.

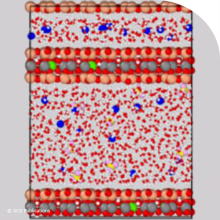

Various gases are produced by metal corrosion and organic material degradation in deep gelological repository for nuclear waste. To ensure repository safety, it's important to demonstrate that gases can be dissipated by diffusion in host rocks and prevent pressure buildup in repository near field. Smectite mineral particles form a pore network that is usually saturated with water, making gas diffusion the primary transport mechanism.

The plans for a new NPP in Slovakia are manged by the company JESS. The first milestone for reaching this aim is to obtain a siting permit for this new NPP.

In January 2023 Italy registered National Assistance Capabilities to the IAEA Response and Assistance Network, RANET. These capabilities are provided by ENEA and offered to requesting Member States.

The tests at all power level were carried out successfully and the complete functionality of the 3rd unit and the achievement of the project parameters was confirmed by a 144-hour trial run at full power, which will finalize the energy start-up stage.

Pagination

Stay informed - subscribe to our newsletter.

Copyright · All rights reserved